Oil smoke filtration from Nederman helps Gillette be their best every day

Gillette has invested in a Nederman Filtac solution to carry out operations in a more efficient and sustainable way in Lodz, Poland. With Nederman’s solution the company will achieve a better work environment with efficient oil smoke filtration and much less frequent filter replacements

Customer Name: Gillette

Country: Poland

Product: Filtac OSF 3x3500

Key Benefit: Improved work environment and production efficiency

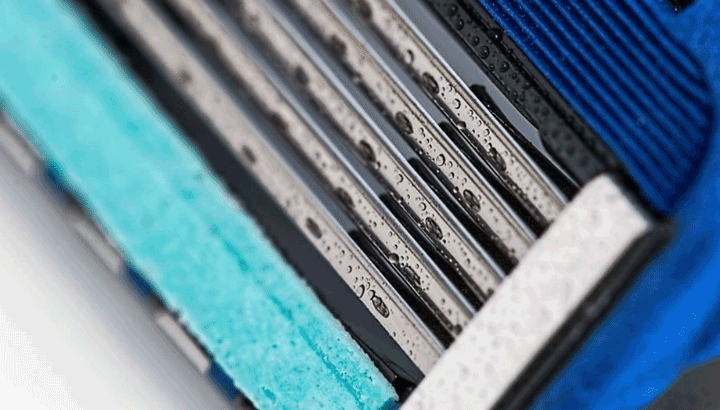

Gillette has been at the heart of men’s grooming for over 100 years. Each day, more than 800 million men around the world trust their faces and skin to Gillette’s innovative razors and shaving products. This commitment to giving men the very best is carried into Gillette’s line of personal care products. All designed for the unique needs of men – helping them to look, feel and be their best every day. Since 2005, Gillette is part of Procter & Gamble.

Challenges

Gillette currently has separate filters for each of their six manufacturing lines with insufficient filtration capacity for today’s operations, running continuously 24/7.

Reason / Impact

By investing in a Nederman Filtac solution with only one unit servicing all six manufacturing lines, Gillette improves the filtration efficiency and reduces the number of filter replacements, resulting in a better work environment and improved production efficiency.

Solution

Nederman’s solution consists of a Nederman Filtac unit OSF 3500 *3, Combifab fans with special design, complete control system and QFS ducting. Nederman is involved from planning and system design to installation and commissioning.

Loading...