- Home

- Industries

Defense

Clean air in defense, military equipment and service centers

Dust, fume, oil mist, diesel exhaust are all common airborne contaminants within facilities that manufacturer or service defense equipment. Welding, metal working, grinding, finishing, composite processing or vehicle exhaust are all applications that create contaminant that workers need to be protected from. Many of these processes produce toxic contaminant that pose a significant worker risk when inhaled. Many of these materials are also considered combustible dust that create a risk of fire or explosion that must be mitigated.

Air filtration and vehicle exhaust solutions for military equipment manufacturing

As the world’s leading provider of industrial air filtration and vehicle exhaust equipment, we are your total solution provider for military equipment manufacturing and service facilities. With our broad solution range, experience and expertise we guide you through the challenges and help you improve the efficiency and safety of your workers, and facility.

Combustible dust challenges in the arms industry

Many of the materials used within military and defense products would be considered combustible dust. Metal dusts, titanium, composites, aluminum and powders all pose a significant fire or explosion threat. It is imperative to capture and filter the dust in accordance with the latest ATEX- or NFPA- standards to mitigate the risk it poses to workers and the facilities. Nederman's solutions, experience and expertise help manufacturers across all defense industries to stay compliant and reduce risks of fire and explosions.

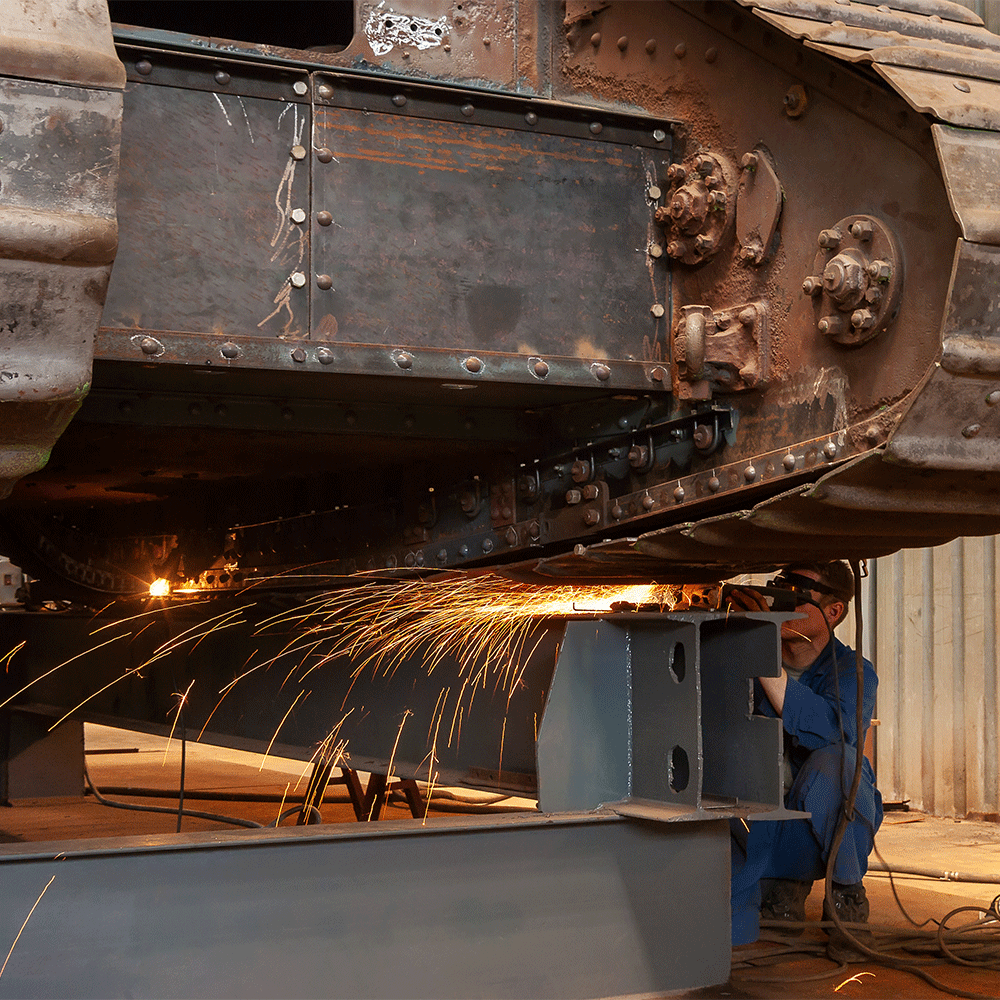

Exposure to toxic weld fumes and smoke in military equipment manufacturing

Welding and metal fabrication are an important process for many military and defense products. Shipbuilding, aircraft, armored vehicles all require heavy welding and generate a lot of smoke and fume. Weld fume has been found to be a Class I carcinogen and thus capturing and controlling these fumes is essential to ensure safe and productive working conditions. Nederman offers a wide range of solutions for local source capture, on-torch and ambient fume extraction for large assemblies that can reduce fume exposure and stay within acceptable exposure limits.

Protecting service and maintenance teams from hazardous vehicle exhaust and welding fumes

Servicing and maintaining military vehicles often requires operating them indoors. The diesel exhaust from these vehicles is a known carcinogen and presents a significant risk to the technicians and staff within the facility. We offer source exhaust extraction solutions and hose reels that prevent exposure for a wide range of vehicle and workshop arrangements.

For welding repair work, we also offers portable fume extraction equipment that can used for confined space or difficult to reach locations common in ship building industry.

Cybersecurity in the defense industry

For defence contractors, working with suppliers that take cyber security seriously is essential. Some governments are now mandating that suppliers follow procedures or obtain a 3rd party accrediation for their cyber security. Nederman takes this requirement seriously and has recently received our Cyber Essentials Accreditation within the UK and our Insight control automation panels are certified to IEC 62443-4-1. Nederman is committed to the continuous investment required to stay ahead of these threats and strengthen our organization and product offerings.

Loading...