- Home

- Industries

Metalworking

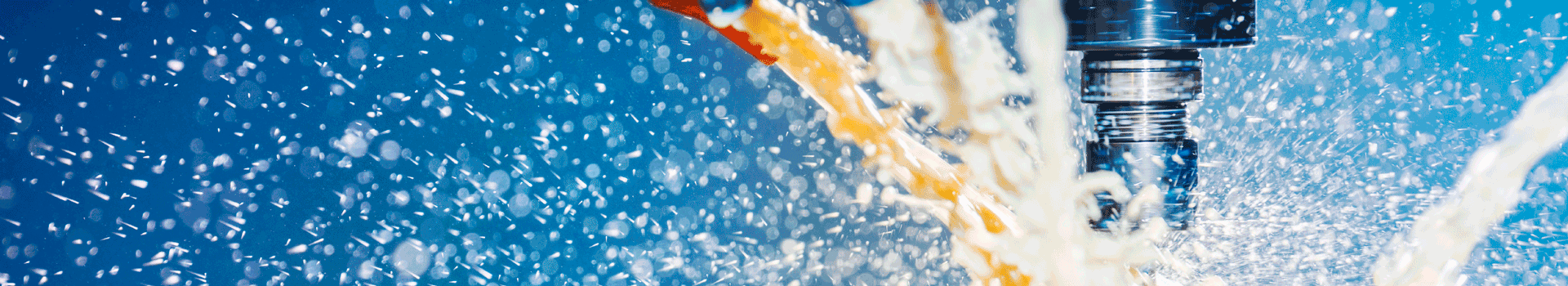

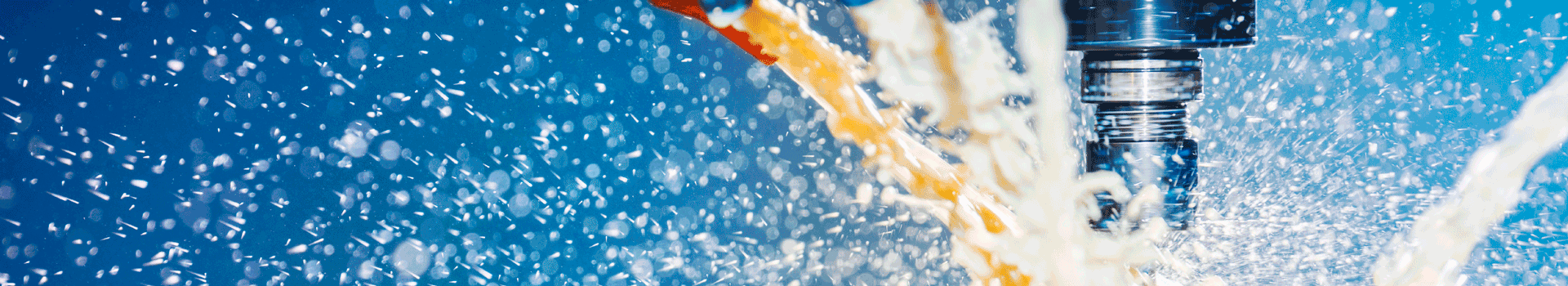

Clean Air Solutions for Metalworking Industry

Optimize production with oil mist filtration and industrial housekeeping

Metalworking environments—whether in workshops, factories, or large production facilities—are characterized by hazardous airborne contaminants. Processes such as welding, grinding, cutting, and machining generate fumes, dust, and oil mist, all of which must be efficiently controlled to ensure worker safety, protect equipment, and maintain air quality.

Nederman provides a complete range of portable, mobile, and stationary air filtration solutions to address the diverse challenges in metalworking. Our expertise spans advanced systems for capturing harmful emissions, including ambient air solutions, dust extraction systems, and solutions for general cleaning and housekeeping, ensuring a safer and more productive workplace.

Combustible Dust Challenges in Metalworking

Handling combustible metals such as aluminum and magnesium presents a unique challenge in metalworking. Dust and fume capture at the source, combined with compliance to strict safety standards, is necessary to prevent fires or explosions. Nederman’s solutions provide reliable, high-efficiency filtration systems, designed to capture and manage these hazardous materials, reducing the risk to both workers and facilities.

Exposure to Toxic Fumes in Welding and Cutting

Welding and thermal cutting produce fumes and smoke that can pose significant health hazards. Nederman's fume extraction systems efficiently capture and filter these airborne contaminants at the source, protecting workers from toxic exposure and ensuring a cleaner, safer workspace. Our systems are designed to handle high fume generation processes, maintaining air quality and productivity in even the most demanding environments.

Achieving Worker Safety and Compliance

Maintaining compliance with safety regulations is crucial in metalworking. Nederman’s advanced solutions provide complete air filtration for localized and ambient air quality management, helping metalworking facilities adhere to the latest safety standards. With a focus on worker safety and facility protection, we offer systems that reduce exposure to harmful contaminants, prevent accidents, and promote a healthier work environment.

Driving Efficiency and Environmental Impact

Our solutions are designed with sustainability in mind, ensuring energy-efficient operation and reduced environmental impact. Nederman’s systems not only improve air quality but also allow for the reclamation of valuable metal materials, contributing to a more sustainable and profitable operation. Additionally, by minimizing the risk of equipment damage from dust and mist, our solutions enhance productivity by reducing downtime and maintenance needs.

Loading...