A Turnkey Solution for Multiple Extraction Systems

How Nederman provided multiple extraction solutions for one facility

When you need solutions for multiple particulate control, it isn’t worth overcomplicating things. It makes sense to work with someone who can handle it all for you.

We recently completed an integration of a large suite of multiple turnkey extraction systems at the Northern Regional College (NRC) in Ballymena, Northern Ireland.

The NRC is one of the main providers of further education in Northern Ireland, teaching thousands of students and apprentices in Science, Health, Advanced Technologies and more. Some of their state of the art workshops required updated, state of the art extraction systems to improve air quality.

Project Overview: A Multi-System Approach

The key challenge set to us was to provide effective, compliant, energy-efficient local exhaust ventilation (LEV) across highly varied training environments. We managed the design, supply, manufacture, and installation of the following critical extraction systems:

- Wood Dust Extraction for the main woodworking workshop.

- Welding Fume Extraction for three distinct welding areas, including robotic welding.

- Vehicle Exhaust Extraction for two dedicated automotive training bays.

Each system was commissioned, tested, and certified in full compliance with current health and safety requirements, guaranteeing a cleaner, and safer learning and working environment for both students and staff.

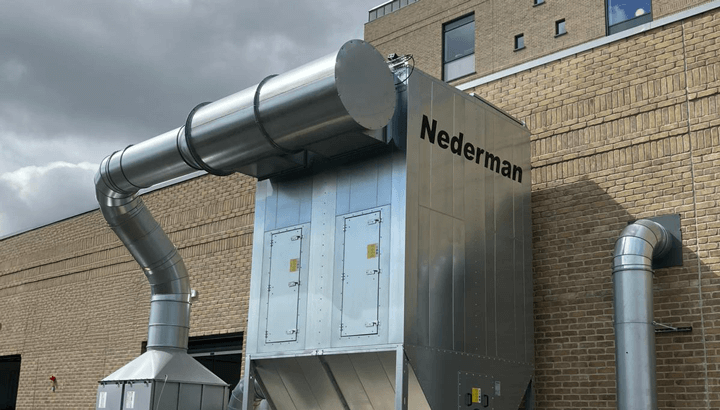

Advanced Wood Dust Extraction System

The NRC’s woodworking facility required a robust, high-efficiency extraction solution to not only control airborne wood dust but meet ATEX standards for potentially explosive dust.

Key Features and Specifications:

- Extraction Points: Direct extraction connections to eleven woodworking machines, including routers, spindle m

- oulders, circular saws, and planers.

- Filtration: External, ATEX-rated Nederman LBR-B filter unit equipped with:

- Airflow Management: A high-efficiency CombiFab FZ56-R355 15kW fan operating via an inverter drive for energy optimisation.

- Ductwork: Galvanised steel smooth bore ductwork (QF) installed at a high level for low resistance.

- Monitoring: Integrated Insight Control Panel for real-time performance monitoring and cloud-based analytics.

This dust extraction system delivers significantly improved air quality, optimised performance with real-time monitoring, and enhances worker and facility safety through its comprehensive ATEX compliance.

Specialised Welding Fume Extraction Systems

Nederman installed four distinct systems to manage the hazardous fumes generated in the welding workshops:

| Area | System Details | Key Features | Performance |

| Main Welding Workshops (2 Systems) | Two identical low vacuum systems, each serving eight welding bays (16 total). | 16 Nederman Ø160mm Telescopic Extraction Arms. Motorised dampers (MDA type) automatically open/close based on welding torch activity for optimal energy efficiency. High-level QF ductwork with BSB fire dampers. | Total airflow of 7,040 m3/hr per system, ensuring high-efficiency local extraction. |

| Oxy/Acetylene Booths | Dedicated system for four booths. | 4 x Ø160mm extraction arms with motorised dampers. Nederman NF 4kW fan with inverter drive. | Airflow of 3,520 m3/hr. Intelligent fan control adjusts extraction based on use. |

| Robot Welding Station | Canopy extraction hood above the automated welding cell. | Nederman N29 2.2kW fan with high-efficiency galvanised ductwork. | Airflow of 1,404 m3/hr, providing reliable, continuous fume removal. |

All welding extraction fans are mounted externally, inverter-driven for intelligent airflow control, and designed to exceed required capture levels in accordance with HSG 258.

Vehicle Exhaust Extraction Systems

Two identical low vacuum systems were installed for the automotive training bays to safely remove exhaust gases during vehicle operation:

- System Components: 2 x Series 865 spring-recoiled exhaust reels with 10m hoses.

- Control: Hoses feature automatic microswitches that trigger the external Nederman N24 0.9kW fan to start and stop when the hoses are engaged/disengaged, ensuring compliance with occupational exposure limits and saving energy.

- Performance: Airflow of 560 m3/hr per system.

Health, Safety, and Compliance

The entire project was executed and commissioned to the highest standards, ensuring long-term safety and regulatory adherence. The NRC now benefits from:

- Full Regulatory Compliance: Certified conformity with COSHH, HSG 258, and ATEX regulations.

- Commissioning and Training: Certified explosion relief and isolation components, on-site operator training, and comprehensive operation and maintenance manuals.

- Ongoing Support: The college benefits from Nederman's service contracts, which include regular LEV testing and certification, preventative maintenance, and technical support, guaranteeing continued reliable, safe and compliant operation.

By choosing Nederman for their extraction system upgrade, Ballymena NRC achieved:

- Cleaner, Safer Workshops: Improved air quality across woodworking, welding, and automotive training workshops.

- Reduced Energy Consumption: Lower operating costs through intelligent inverter-driven fan technology and demand-based control systems. Recirculating system in the wood workshop to return the warm, filtered air back into the workspace.

- Future-Proof Infrastructure: Systems designed with the potential for capacity expansion and backed by long-term service and compliance support.

Nederman’s end-to-end expertise in industrial air filtration provides the NRC with a turnkey solution that prioritises worker health, environmental compliance, and operational efficiency, setting a high standard for modern technical college facilities.

Looking for an Extraction and Filtration System in Ireland?

If your business needs a turnkey extraction solution or other industrial air filtration systems, contact Nederman today to discuss how we can help create a safer, compliant, and more efficient workplace for you.